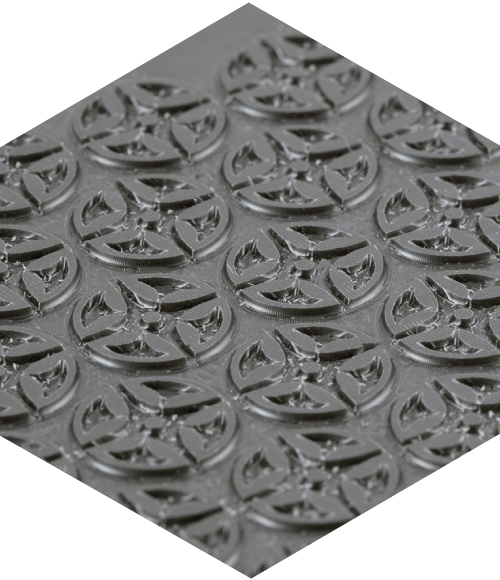

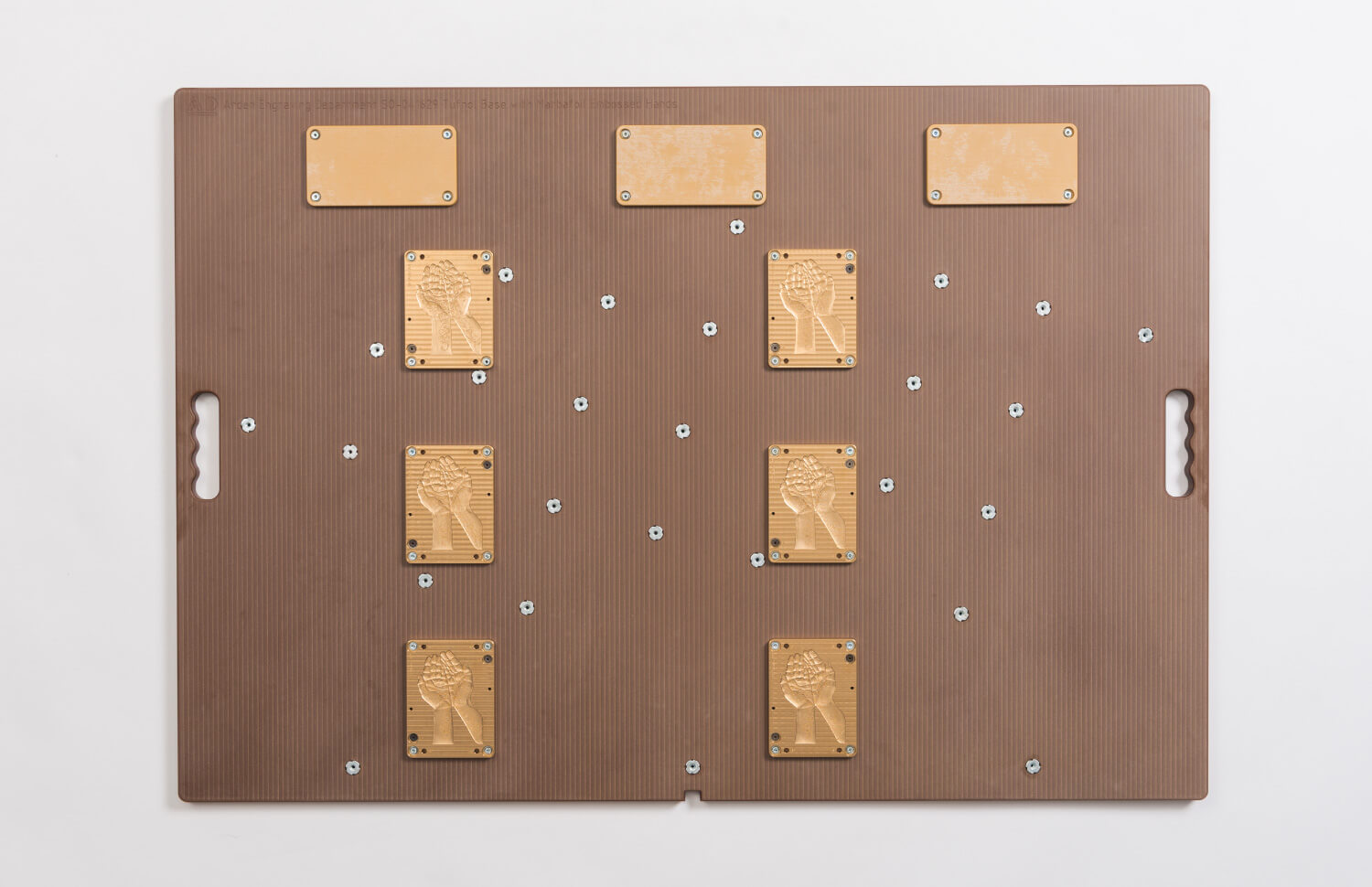

Deboss Family

Our deboss tooling is produced with a precise calculation to offer excellent conversion results and avoid adverse marking on the finished substrate.

All deboss tooling can be supplied in either brass or from our flex range of durable plastic materials, which are 100% recyclable.

Ad

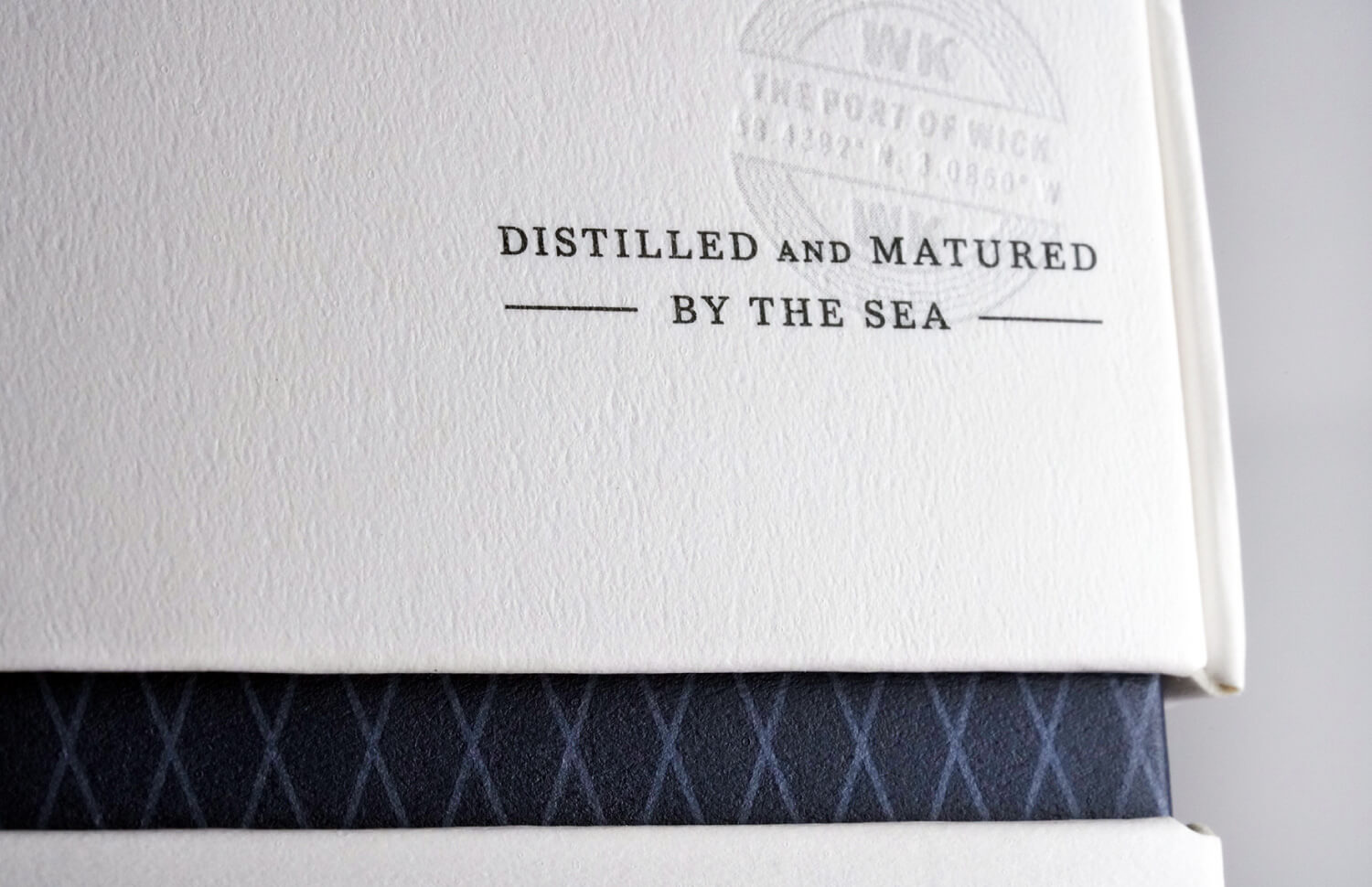

Brass Deboss

Deboss Family

Our deboss tooling is produced with a precise calculation to offer excellent conversion results and avoid adverse marking on the finished substrate.

All deboss tooling can be supplied in either brass or from our flex range of durable plastic materials, which are 100% recyclable.

Afd

Arden Flex Deboss

Associated Accessories

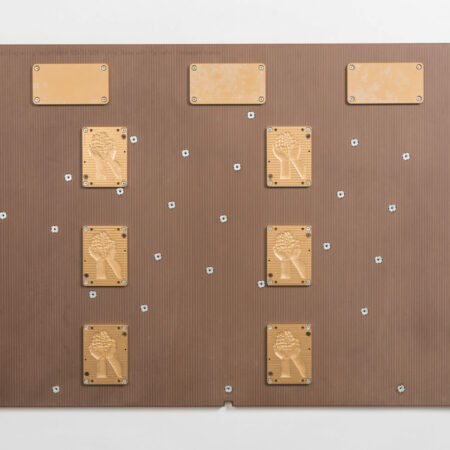

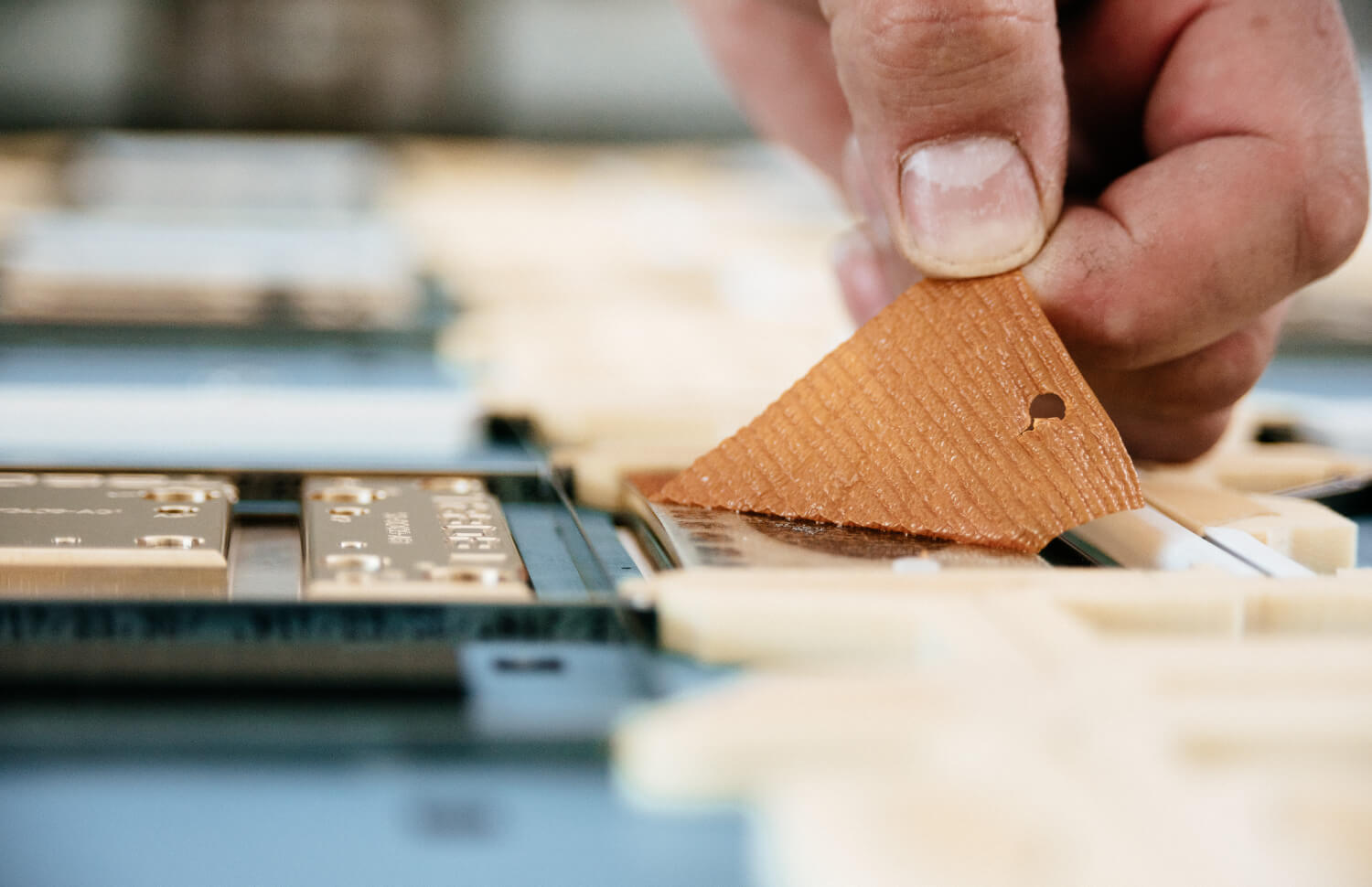

Embossing Base System

This precision milled product is designed for fast and accurate set-up of a first pass embossing. All embossing dies are mounted to the precise dimensions of your layout file with the use of our zero pins. We can also supply balance blocks at the back of the base to ensure your machine is running to its optimum performance and offering long-term protection to your converting machine.

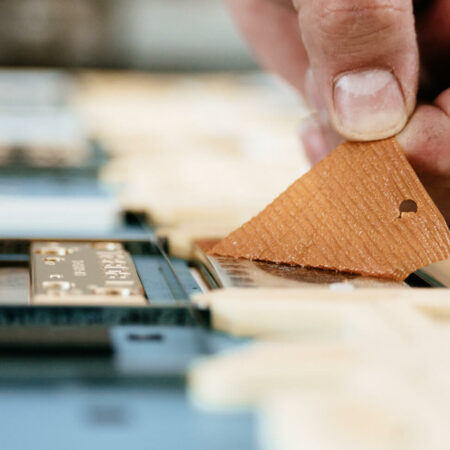

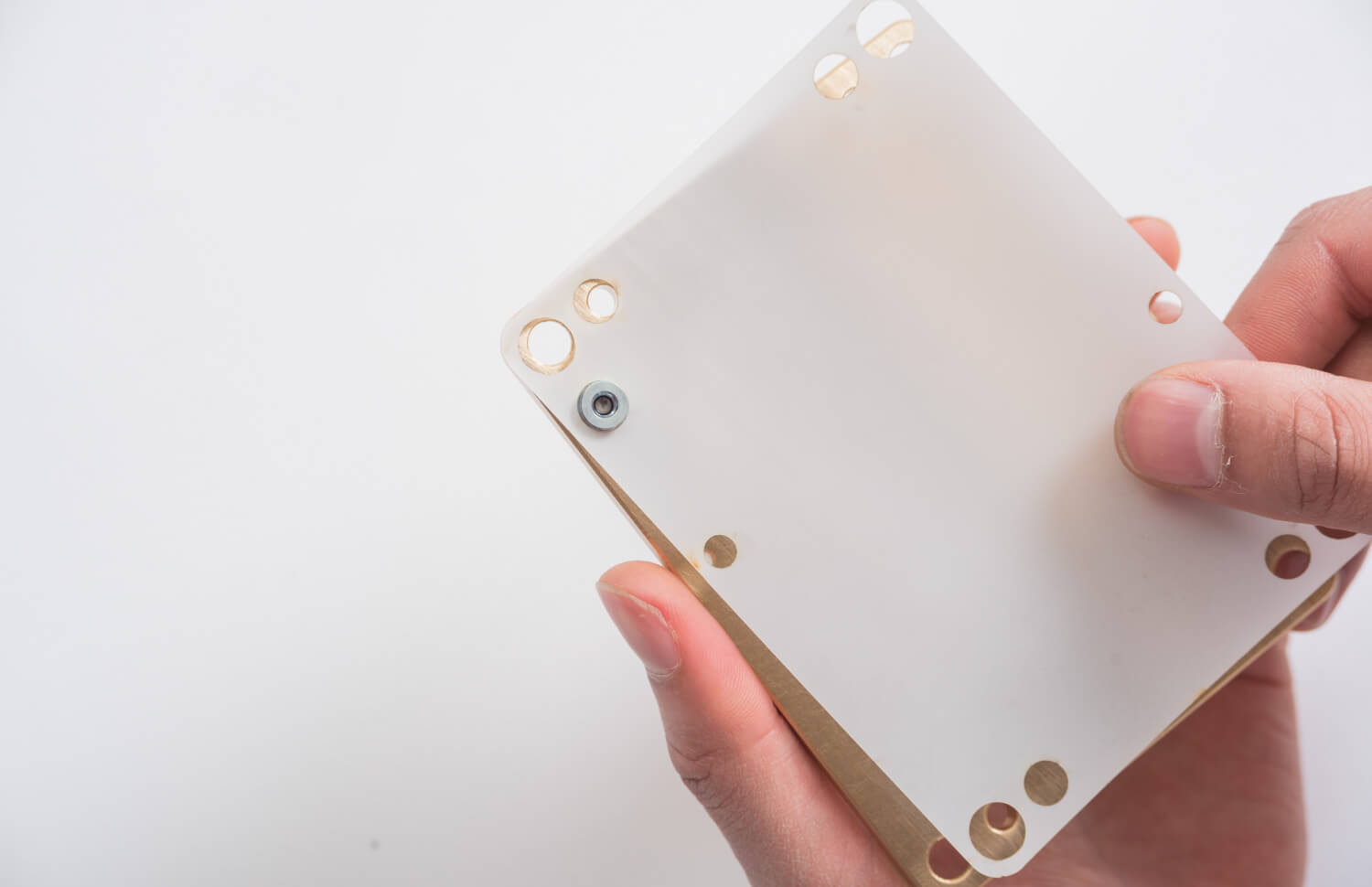

Memory Pins and Shims

Our pins enable the tool to be lifted and returned into the exact position from which it was taken, allowing for the insertion of embossing shims to achieve the desired embossing height.

Adhesive Pad

We can supply all your male forces with an adhesive backing. This ensures the tooling is press-ready and saves your machine operators applying the adhesive on press.

Zero Pin

These simple location pins are supplied to fix each die to the precise ‘zero’ position in relation to your layout file. It is this level of detail that ensures your tooling will be set up as accurately as possible, saving valuable set-up time and reducing your costs.

MSP Pins and Applicator

The MSP system offers an extremely quick, precise and effective method of transferring the embossing counterforce to the machine cutting plate. The pins come with an ergonomically designed applicator for easy application and removal.