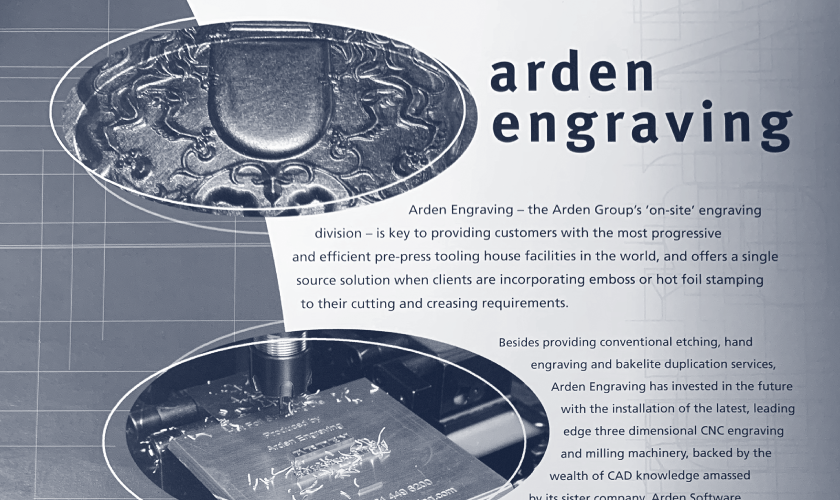

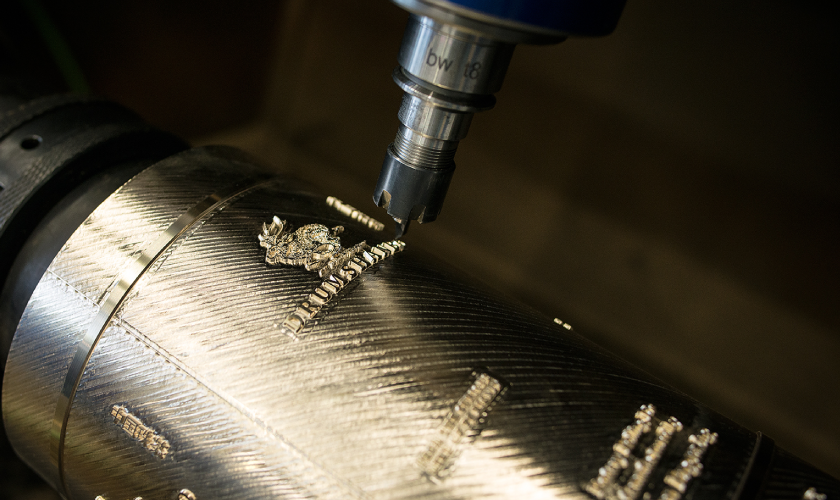

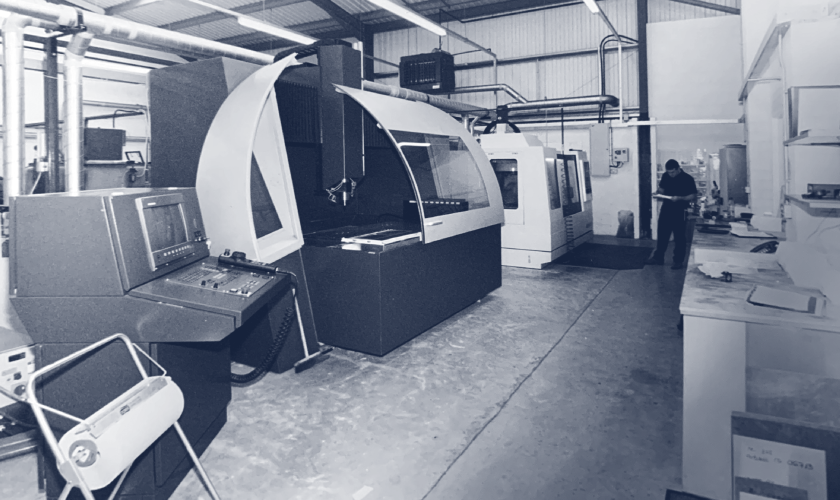

With a continued desire to invest in the future of the business, Arden Engraving built on our portfolio of machinery to include new CNC engraving centres to increase our capacity to become the largest facility of its type in the UK.

With the Arden Group keen to continue its global expansion, in partnership with Marbach GmbH, we launched an engraving production facility in Charlotte, NC, USA in July 2012, which has gone from strength to strength.

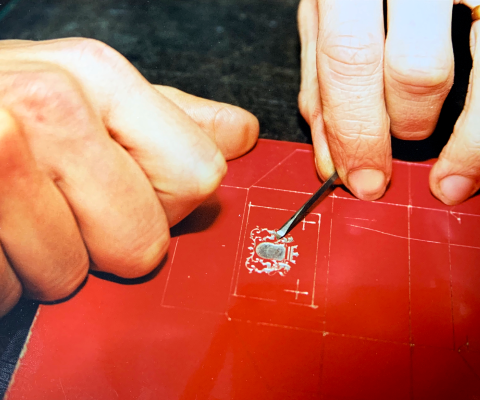

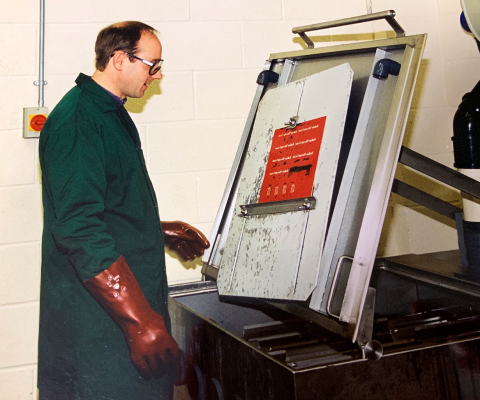

In 2015 we introduced a laser engraving facility capable of producing the finest detail engraving where CNC or the chemical etching process cannot provide the necessary depth to achieve perfect reversed out results as well as incredibly small text and other delicate detail - it was ideal for the label industry which was to be the next route of our expansion.

Thanks to the success of the USA division, we set our sights on the European market, launching Arden Engraving Germany in 2018, investing in new state-of-the-art CNC machines, to further extend our reach into markets within mainland Europe.

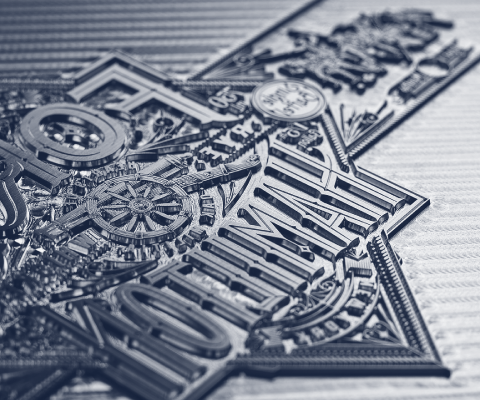

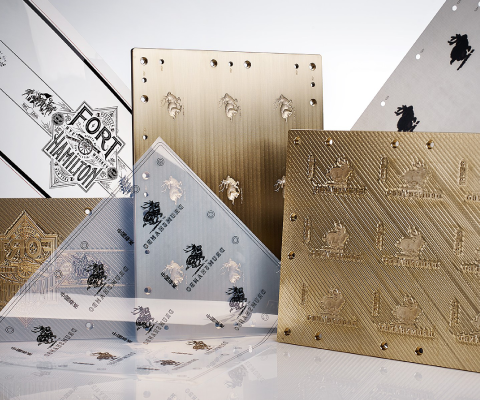

In 2018, Arden Engraving expanded into the label market. After supplying embossing and hot foil stamping tools to the carton industry for two decades, Arden's engraving division began making its mark on the label market, offering advanced rotary and flatbed tooling solutions to some of the largest label manufacturers in the world.

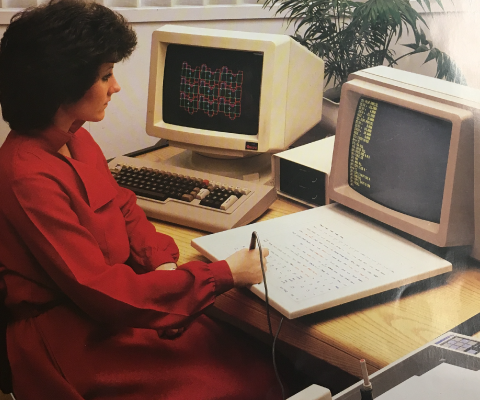

We invested heavily in the latest CNC engraving machinery and advanced laser technologies to provide highly precise foil stamping tooling to help ensure our customers are making the right impression.

Towards the end of 2020, we underwent a major rebrand with a fresh modern look and a new website. Our new, secondary logo, which is used alongside our original eagle emblem, is inspired by the carton outlines from Arden Sofware’s packaging design CAD software Impact; while the new website showcases the full range of products and tooling solutions for die-making and engraving.